World leaders in design, prefabrication, installation and technical assistance in G.R.E. (GlassFiber Reinforced Epoxy) piping system and G.R.P. (GlassFiber Reinforced Plastic) structures

Official Distributor and Installer:

Excellence in management system for more than

Water Treatment Projects

- Feed Water

- Effluents

- Flocculation

- Vents

- Water Lines

- Waste Pits

- Chlorination

- Chemical Sludge

- Aeration

- DCI Systems

Offshore Wind Projects and Green Energies

- DCI System

- Scrubber

- Caissons / Wells

- Process, Cooling and Drinking Water

- Grey Water Lines and Black Waters

- Deck Drains / Caps

- Drilling sludge

- Brine and water treatment

- Ballasts / Trimming

- Crude Oil Lines and Oil Tank Washing

- Inert Gas System

- Probes

- Bilge Lines

- Cleaning of Tanks

- Water Purification Systems

Oil&Gas, Industry and Petrochemical Projects

- DCI Lines

- De-loading

- Slops

- Plant Cooling

- Chemical Sludge

- Crude Oil and Hydrocarbons

- General Water Services

- Process Residual Treatments

- Process Water Lines

- Cooling Lines

- Scrubbers

- Brine

- Equipment Drains

- Outfalls

- Vents

Marine Projects

- DCI System

- Scrubber

- Caissons / Wells

- Process, Cooling and Drinking Water

- Grey Water Lines and Black Waters

- Deck Drains / Caps

- Drilling sludge

- Brine and water treatment

- Ballasts / Trimming

- Crude Oil Lines and Oil Tank Washing

- Inert Gas System

- Probes

- Bilge Lines

- Cleaning of Tanks

- Water Purification Systems

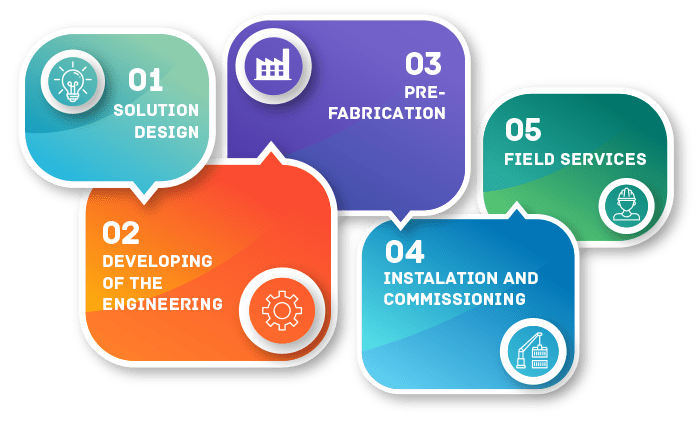

SERVICES

- System of Pipes and structures in Composite G.R.E. and G.R.P.

- R&D in composite: "If it doesn't exist, we'll create it"

-

Steel Pipe Rehabilitation System with Composite Technology

- Metallic structures and supports

- Metallic and thermoplastic piping system

- Engineering services

- Inspection and definition of intervention plans

- On-board technical assistance

- Modular Integration of Piping and Equipment on Skids

ENGINEERING

PIPING SYSTEM DESIGN

Technical specifications, 3D Design, Routing, P&ID Verifications, General Provisions, Isometrics of manufacturing and assembly with associated support, for projects of composite (G.R.E.) and thermoplastic piping systems.

DESIGN CONVERSION OF METALLIC TO COMPOSITE AND THERMOPLASTIC PIPING SYSTEMS

Inspections and feasibility studies for the conversion of piping systems made of metallic materials (A. Carbon, A. Stainless, Cuni, etc.) into composite (G.R.E.) and thermoplastic piping systems.

STUDY OF SURGE AND STRESS ANALYSIS

Flexibility, surge and stress analysis in G.R.E. piping systems: Study and optimization of results: Positioning and support loads, study of admissible loads in equipment according to current regulations and required design codes.

COMPOSITE JACKET CALCULATION  FOR PIPE REINTEGRATION METALLIC

FOR PIPE REINTEGRATION METALLIC

Rehabilitation of metal piping systems due to wall loss or leaks due to external corrosion, without the need for disassembly.

DESIGN OF COMPOSITE ELEMENTS

Design and manufacture of industrial elements and goods as well as structural elements in composite “fit for purpose”.

SUPPORT DESIGN AND STRUCTURES

Design and manufacture of metal supports, preparation of catalogs and types of supports according to the project and project needs.

Design and manufacture of modular metal structures for piping system projects (frames, hoists, platforms, idlers…)

Design and manufacture of structures in F.R.P. material: railings, ropes…

SUSTAINABILITY

SUSTAINABILITY

Pipespain has developed a technology  that extends life useful life of the steel lines, avoiding the need for renovation, reducing production energy costs, as well as the carbon footprint.

that extends life useful life of the steel lines, avoiding the need for renovation, reducing production energy costs, as well as the carbon footprint.

reduces 50% of energy consumption during its production compared to metal pipes and reduces energy use by up to 90% during its useful life due to a lower pumping power requirement (scaling action) and a better permanent flow coefficient.

reduces 50% of energy consumption during its production compared to metal pipes and reduces energy use by up to 90% during its useful life due to a lower pumping power requirement (scaling action) and a better permanent flow coefficient.

A world that needs to reduce CO2 emissions and seeks clean energy sources is opening the door to G.R.E. in all sectors related to green energy generation such as offshore wind power generation and green hydrogen generation plants. PIPESPAIN is working to identify new applications for composite pipes, equipment and structures, supporting the sustainability of our planet and moving towards a New Future.

Our Commitment

QHSE

CORPORATE COMPLIANCE

SOCIAL RESPONSABILITY

Pipespain S.L. – All Rights Reserved ® 2026 – Design: Suzumes.com

Design: Suzumes.com